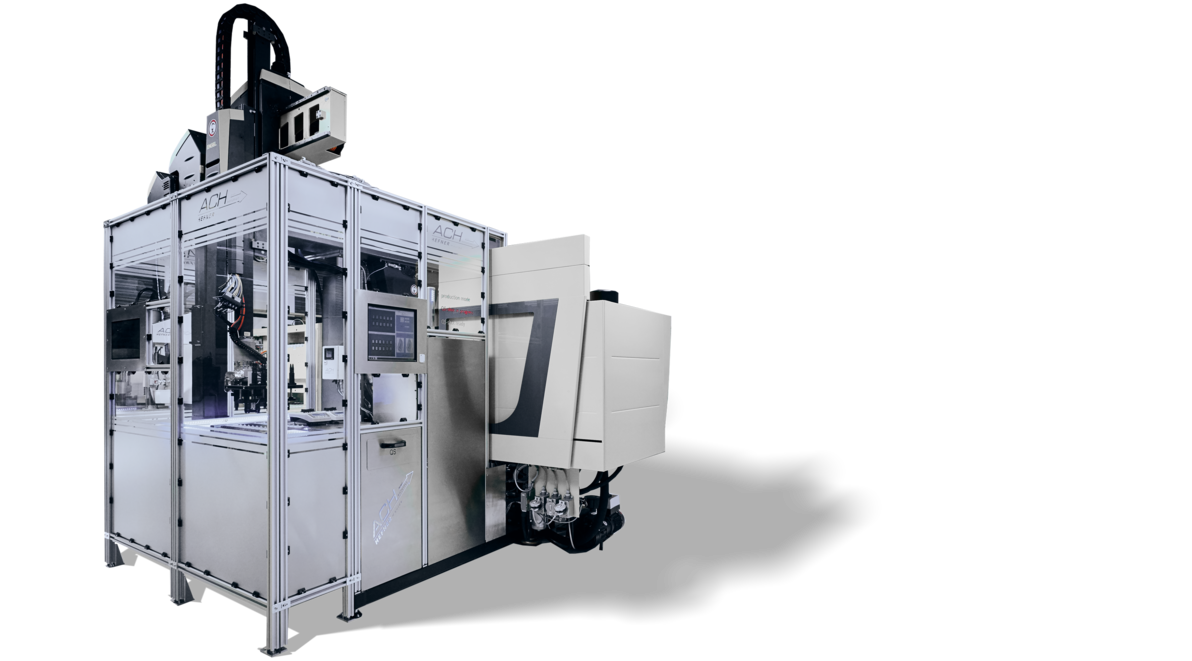

Your turn-key partner in silicone rubber processing

We consider your trust to be our greatest incentive.

As the general contractor responsible for your project, we guarantee a flawless overall solution

Our decades of experience and diligence make all the difference.

From initial contact to handover and training, we seamlessly integrate all areas to ensure a flawless process from idea to finished product.

Our teamwork, short communication channels, and in-house expertise enable perfect project execution.

We have always enjoyed the challenges presented by customer projects and have grown alongside them.

- Product development.

- All competencies are in-house.

- General contractor for your project.

Diligence

makes

the Difference.

ASSISTANCE WITH PRODUCT DEVELOPMENT

We can help bring your concrete idea to life with our expertise and experience.

Through close collaboration, we can develop the best solution to meet your requirements.

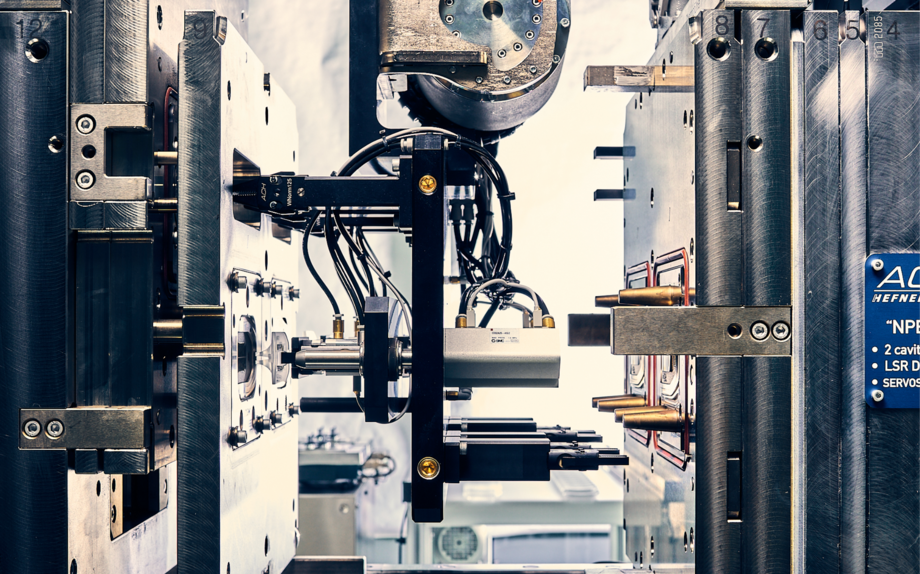

TOOL MAKING

Tool Making is one of our core competencies.

The molds designed by our engineering department are manufactured and tested in-house with diligence and precision. We take pride in having all of our toolmaking skills in-house, which ensures the highest quality for the heart of the system.

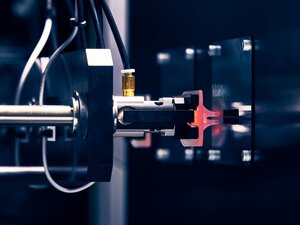

Cold runner technology

As with toolmaking, diligence and precision are equally important in cold runner technology. We manufacture the components ourselves and adapt the cold runner to your specific requirements.

ACH Solution has developed nozzle technology, process data processing, and self-regulation that enable efficient and environmentally friendly operation.

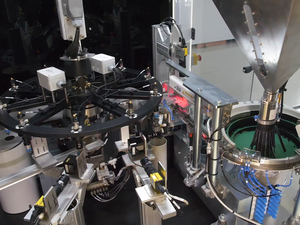

Automation

The automation tasks include demoulding, the patented ACH SERVOSHOT® 2G NV self-regulating system, ACH MOLD 4.0 process data processing, printing, separation, and packaging of parts.

With ACH MOLD 4.0, parts printed inline with a code (DMC) can be seamlessly assigned to cavities, shots, and process data. Inline inspections, when used with our ACH SERVOSHOT® 2G, automatically adjust the material feed and nozzle settings to ensure optimal part quality. Additionally, our stand-alone testing machines allow for autonomous part testing outside of the system.

Our automation team's specialists are capable of overcoming any challenge, resulting in optimized automated processes for your economic benefit.

Innovative Dosing technology

Our innovative dosing technology meets all requirements for optimal material feed. We provide customized solutions for each application to ensure smooth production.

Our dosing pumps optimize material utilization (residual quantity in the container < 1%) while consuming minimal energy. This not only saves money but also protects the environment.

INITIAL SAMPLING

The finished tool is mounted in the machine provided for this purpose in our production halls and first sampled directly in the final configuration. Our accuracy and precision also make the difference in this process. We are only satisfied with the result when the system produces perfect items that meet all the defined requirements.

Customer Acceptance, Training and Commissioning On-Site

We conduct an acceptance test of the entire system under production conditions at our premises before delivery.

Our application engineers will train your team on the system and conduct joint tool training sessions. Additionally, our technicians can provide expert support during system commissioning.

For US customer, there is a tech center in Florida available.

Service

The partnership resulting from a project is significant to us.

Therefore, we offer a wide range of services to simplify optimization, maintenance, and servicing for you.

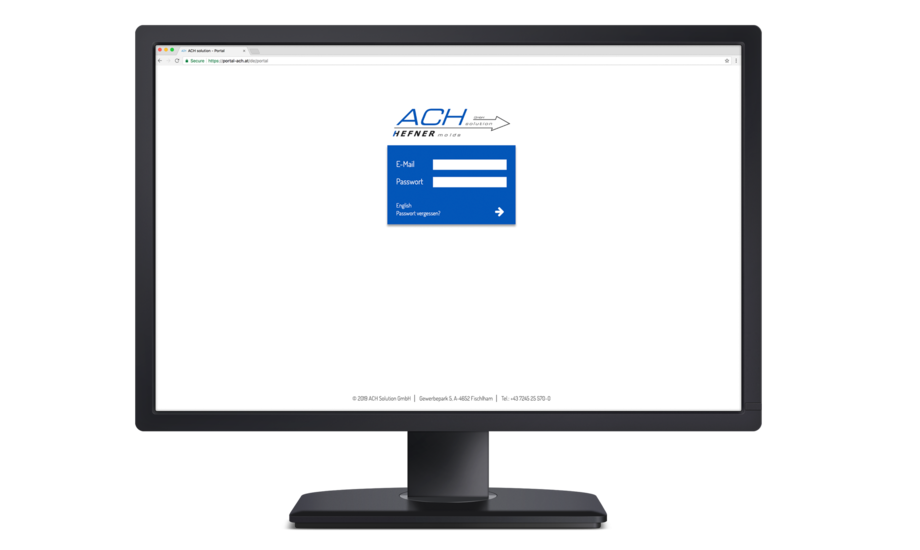

We provide every customer with all relevant data in our customer portal, which is accessible from anywhere in the world at any time - ACH Service plus.

Additionally, we have a Tech Center in Florida to provide better quality customer support for our US customers.

Download: Folder

INNOVATION IN Silicone processing

Contains all the information about our dispensing technology in a compact format.

Spare parts request

Request spare parts online

In our customer portal, you can conveniently request and retrieve spare parts and access all relevant product details.