INNOVATIVE DOSIng technology

Manufacturers of molded silicone articles face new challenges in processing silicone rubbers. They must achieve high part quality while dealing with an increasing variety of silicone types with unique processing properties. This requires a flexible system technology.

Our innovative ACH Solution dosing systems meet all known and future requirements at the highest level.

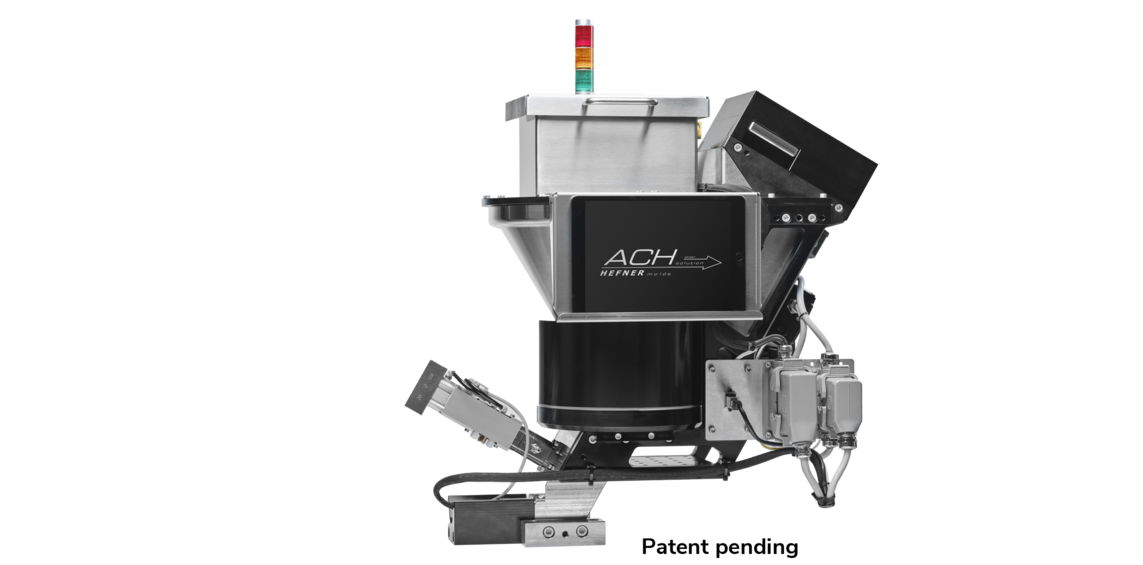

Our new ACH TURNMIX HTV dosing technology allows for processing solid silicone (HTV) with Shore hardnesses ranging from Shore A 20 to Shore A 80.

The ACH TURNMIX is a stand-alone system that can communicate with various control systems through existing interfaces.

Diligence

makes

the Difference.

Dosing Technology for Liquid Silicone

LSR is short for Liquid Silicone Rubber, a low-viscosity material that hardens when heated through vulcanization.

Dosing technology for solid silicone

HTV solid silicone is a higher-viscosity material that hardens when heated through vulcanization, as opposed to LSR.

Download: Folder

INNOVATIVE DOSING TECHNOLOGY FOR LIQUID SILICONE RUBBER

This document contains all the information about our dosing technology in a concise format.

Spare parts

Request spare parts online

In our customer portal, you can conveniently request and retrieve spare parts and access all relevant product details.