Our innovations

We are not satisfied with existing solutions.

The constant quest for improvement drives us to develop new components. Our research and development gives our customers a technological edge that pays off.

- Self-optimizing process control.

- Process data processing.

- Research and development in our working areas.

- Mixed reality for easier maintenance and installation.

Diligence

makes

the Difference.

SELF-OPTIMIZING PROCESS THROUGH

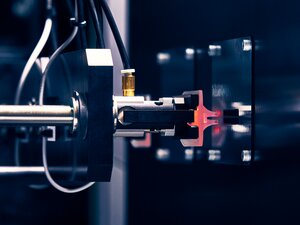

PATENTED ACH SERVOSHOT® 2G

The individually electrically adjustable valve gate system for LSR, HTV, rubber and thermoplastic processing.

Dynamic, stepless and high-precision in-process level adjustment with the patented electro-pneumatic valve gate system ACH SERVOSHOT® 2G results in the fastest possible start-up and the best possible reproducible quality. The subsequent fully automatic quality control enables a self-regulating process, minimizing maintenance costs and waste, and optimizing quality. Thanks to the WIFI or LAN interface, the device is IOT-ready, which means that the user interface and process data can be accessed via the Internet or Intranet if required. Alternatively, a USB interface is available for data transfer.

- Available up to 64 needle valves.

- Needle stroke accuracy of 2μm.

- Saving of parameter datasets on setup unit, operating unit and USB .

- Each cavity / nozzle can be setup independently.

- Single cavity / nozzle can be switched off.

- Maintenance-free, patented ACH SERVOSHOT® 2G unit.

- Flow regulation during operation.

- User-management system with password protection.

- Automatic service position for needle valve.

- Sensor-controlled cavity filling (optional).

- Automatic flow adjustment through part weight control(optional).

Process data processing with ACH MOLD 4.0

ACH MOLD 4.0 monitors material processing and documents all key process data (process pressures, mold temperature, coolant flow, etc.).

The data can be easily retrieved or restored via the WIFI, LAN or USB interface for analysis, process optimization or further processing.

Thanks to the integrated OPC interface, the process data can be integrated into the company's internal process control system.

- Tool process data is automatically stored and can be exported via the USB interface and restored at any time. Process data can be integrated into a process control system via a bus system.

- Mold and material data with lot number.

- Shot counter.

- Mold- & cooling water temperature.

- Air & cooling water pressure.

- Optimization and control of machine parameters.

- Calculation of cycle-time.

- Information of maintenance cycles.

- Occuring errors are logged and can be bound with automatic actions.

- Password protected user management.

- Vacuum monitoring.

instant SERVICE on-site with AUGMENTED REALITY

With our Augmented Reality service, we are always right there with you.

Routines are explained step-by-step, making maintenance a breeze.

Remote assistance allows you to support our technicians in real time - anywhere in the world.

Automated product testing

To ensure the quality of the products, they are continuously tested in a fully automated process.

Various test methods are used. The resulting test data is not only logged, but also used for immediate self-optimization of the process, thus enabling continuous optimum production quality.